Textile heat transfers come in three technologies when it comes to peeling. This can be “hot peel”, “cold peel”, or “hot split”. But what is the difference between them.

First, the main difference lies in the transfer paper or foil.

Cold Peel Heat Transfers

These heat transfers are the oldest type of textile heat transfers. As the name might tell, they must be peeled off in a cold state. This is for the fact, that the transfer paper itself shows a rather strong bond to the print at all temperatures. When trying to peel the transfer paper while the print is still hot the paper will lift the still soft print from the garment. This causes failures in adhesion to the textile and reduce its durability.

Another point worth knowing is, that the transfer should be as cold as possible before peeling. Due to this the print can solidify and the final bond to the textile gets stronger.

Hot Peel Heat Transfers

These heat transfers are produced to be peeled off directly after pressing, when the textile and transfer are still hot. Therefore, the release layer of the transfer paper and the inks are designed to be non-adhesive when hot. By this no time is wasted by waiting for the transfer to cool off before peeling. But it carries a risk.

If the transfer paper does not release properly because it was too cold, the ink will be lifted during the peeling process. This can have a negative impact on the final adhesion and durability of the print. In other words, where the cold peel heat transfers must be cooled off, the hot peel heat transfer needs to keep the heat up.

Hot Split Heat Transfers

This type of transfer is one, where the ink plays a bigger role. Just like with hot peel heat transfers, these must be peeled off when still hot. But other than with hot peel transfers where the release layer is meant to release the whole print. It rather splits the print within the color layer, which is where the name comes from. Due to this a small rest of ink will remain on the transfer paper.

Especially if a vintage look is required or the print should be extra breathable, a hot split heat transfer will do the trick.

Instant-Peel Transfers

Another variant, used especially in DTF printing, is the instant-peel film. This is just one of the many names for a special film. It is designed so that the release coating of the film can be peeled off regardless of the temperature. Thanks to this feature, you can play it safe and let a design with fine elements cool down before peeling it off, or to save time, peel it off right after pressing.

For this reason, such a foil is the standard in our DTF printing for the consumables.

In Short

When having the time to let the transfer cool down before peeling, a cold peel heat transfer is a great choice as it achieves a good bond when applied and peeled off correctly.

In cases where time plays a big roll, like when using transfers in an automatic heat transfer machine, a hot peel transfer is a better choice. Even though these often times cost a little more.

Hot split transfers are the go to when an extra soft feel or a special look is required.

Summed up, none of these is better than the others, just different.

Our Transfer Solutions for You

We have the right foils for you for DTF printing. Especially our Instant-Peel foil, which can be peeled off directly after pressing or once cooled down, is perfect for this process. But also classic Cold Peel films are available. Converted into 100m long rolls with 60cm width they are perfect for every DTF printer.

Furthermore, we can print Transfers for you so that you can apply them yourself. For this we use appropriate foils in combination with the DTF printer - DIGITRAN FlexLine DTF600 MK-II. Benefit from intensive colors, high stretchability and washability.

Click this button to get in touch with us for a personal consultation. To make sure that your products can benefit from this unique, clean and digital printing technology as soon as possible.

Further Posts

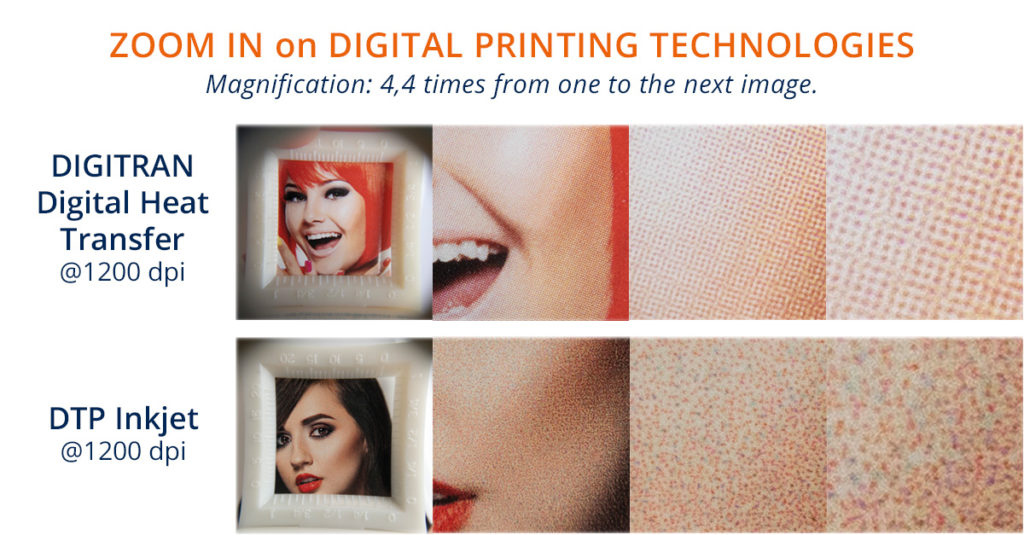

Would you think that 1200dpi and 1200dpi digital printing is the same? You probably would.

But actually no, not even close!

Especially when it comes to photo-realistic printing and skin tones the print quality must be on point. The confusing part is that even though both prints shown in the photo have a resolution of 1200 dpi, they are obviously not the same. But how does that come?

Why cosmetic tubes are perfect promotional products? Because they are compact, useful and give enough space for your message.

And we are here to get them printed, also in small quantities!

As a contract decorator who prints your tubes just in time and in almost any quantity, or as your partner for heat transfer machines as well as digital heat transfer decals, we have the perfect solution for you.

What you should know about the advantages of printing different names, languages, numbers and codes – in one run!

Starting with printing different names on promotional products over serialized special editions to a print run with every image being different. With digital heat transfers you can achieve all this. Without UV, without solvents and without stopping your heat transfer machine.

3 sides, 3 different photo-realistic images.

That is what a paper cube box can look like when you print it with DIGITRAN digital heat transfer technology.

Lip balm comes in pretty much just one shape, which makes the print is even more important for this type of packaging.

With digital heat transfers we ensure that your product will stand out!

Especially when it comes to multi-color designs there is close to none in the shelves. Simply because multi-color designs are difficult to print onto a small lip balm shell and the more colors there are, the more it costs.

To bring more diversity to this product we developed DIGITRAN digital heat transfer decals as well as DIGITRAN heat transfer equipment for it