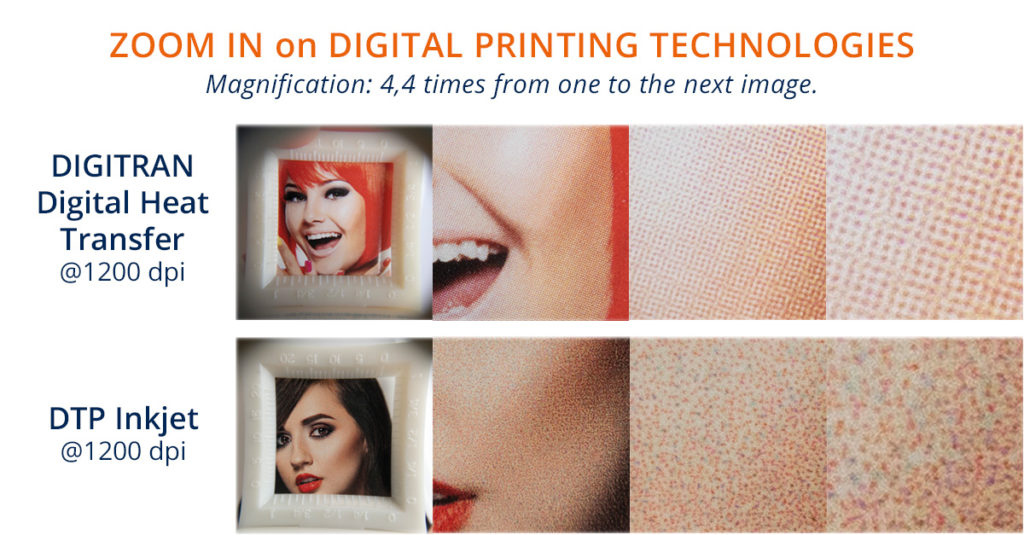

Do you think that 1200dpi and 1200dpi are the same thing in digital printing? Probably yes.

But no, not even close!

Especially when it comes to printing photorealistic designs and skin tones, the best possible print quality should be sought. The only confusing thing is that both images have a print resolution of 1200 dpi, yet they are anything but identical. But where does this difference come from?

Digital Heat Transfers for Printing Shaped Products

DIGITRAN digital heat transfers for printing onto shaped products are printed under highly controlled conditions. For this reason, high-resolution heat transfer images can be printed with accurate positioning of the color dots. The toner-based printing process uses a combination of special transfer foils, high-resolution toner printing and adhesion promoters for various products and materials.

Immediately after the actual printing process, these printed images are wound up into compact rolls and sent for application. The last remaining step is the application of the finished printed image to the product.

Digital Inkjet Direct Printing

Printing with DTP (Direct to Product) inkjet technology is somewhat more difficult, as it involves the application of tiny drops of ink directly onto the product. These drops, up to 2 picoliters in size, have to fly through the air after leaving the print head, land on a moving surface, overcome electrostatic influences and not interact with the other drops. These complex requirements make it more difficult to control the color dots as precisely as with a toner transfer.

Conclusion

Even though both prints have 1200 "dots per inch", this number says nothing more than the number of printed colored dots. And not where these dots are afterwards.

Click this button to get in touch with us for a personal consultation. To make sure that your products can benefit from this unique, clean and digital printing technology as soon as possible.

Further Posts

Matt or glossy? With #DIGITRAN digital heat transfer technology you can have both!

With the correct digital heat transfer decals and heat transfer equipment, you can make this decision even after the transfers have been printed. And that without the use of any varnishes!

Print or get printed – short run solutions for your cosmetic tubes. With DIGITRAN technology you can make that choice. Always digital and with an outstanding quality.

When it comes to short run printing of cosmetic tubes you are often confronted with many problems. Either it is expensive, or you must cutback when it comes to quality. In the worst case your request will be simply declined.

For this reason we have addressed these issues and developed a set of solutions.

Changing designs paired with an ongoing number on a cosmetic tube. Absolutely no problem. You think it, we print it.

These 20ml cosmetic tubes have even more than those two features. Take a close look at the grey line right below the red, ongoing number. Believe it or not, this is a 1-point small text printed in bold or regular style. Besides that

This airless dispenser says it all: Summer is not over, yet!

Printed with digital heat transfers on a DIGITRAN heat transfer machine.

For packing creams there are several solutions including jars or tubes, and there are airless dispensers.

If you want to keep your product safe from drying out or going bad due to air getting inside your packaging, these last one might be the best choice for you.

Especially with your product being a high-quality cream or serum,…

Polypropylene (PP) is a material used in many applications from cosmetics to promotional products due to its properties such as hardness, resistance and costs. However, what are important and desired properties for some are an issue for others. That’s because