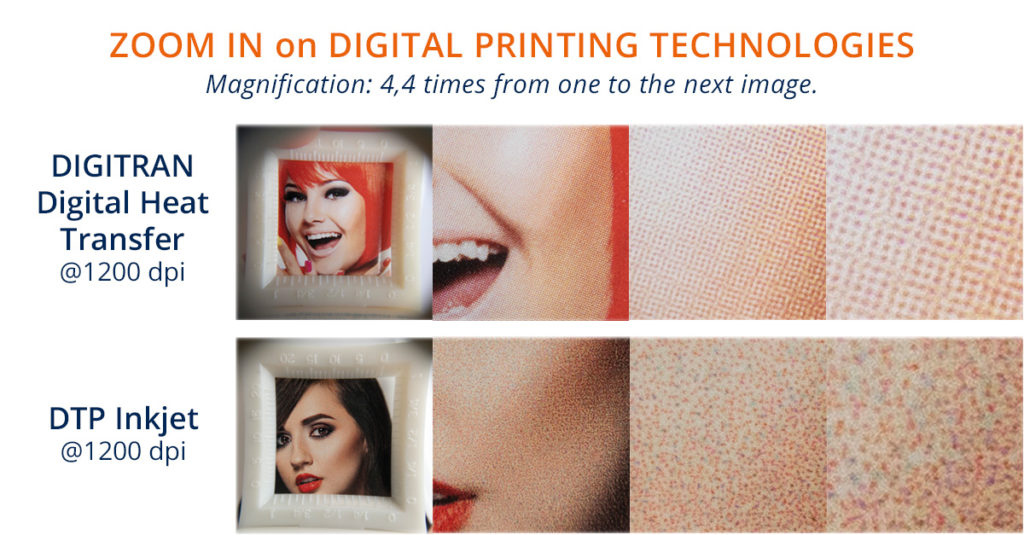

Do you think that 1200dpi and 1200dpi are the same thing in digital printing? Probably yes.

But no, not even close!

Especially when it comes to printing photorealistic designs and skin tones, the best possible print quality should be sought. The only confusing thing is that both images have a print resolution of 1200 dpi, yet they are anything but identical. But where does this difference come from?

Digital Heat Transfers for Printing Shaped Products

DIGITRAN digital heat transfers for printing onto shaped products are printed under highly controlled conditions. For this reason, high-resolution heat transfer images can be printed with accurate positioning of the color dots. The toner-based printing process uses a combination of special transfer foils, high-resolution toner printing and adhesion promoters for various products and materials.

Immediately after the actual printing process, these printed images are wound up into compact rolls and sent for application. The last remaining step is the application of the finished printed image to the product.

Digital Inkjet Direct Printing

Printing with DTP (Direct to Product) inkjet technology is somewhat more difficult, as it involves the application of tiny drops of ink directly onto the product. These drops, up to 2 picoliters in size, have to fly through the air after leaving the print head, land on a moving surface, overcome electrostatic influences and not interact with the other drops. These complex requirements make it more difficult to control the color dots as precisely as with a toner transfer.

Conclusion

Even though both prints have 1200 "dots per inch", this number says nothing more than the number of printed colored dots. And not where these dots are afterwards.

Click this button to get in touch with us for a personal consultation. To make sure that your products can benefit from this unique, clean and digital printing technology as soon as possible.

Further Posts

As heat transfer technology in general is well established for printing mascara bottles, the digital version by DIGITRAN makes it even better!

Here are 7 reasons why:

CMTD – 6 feet of fine art. High-quality digital printing for folding meter sticks – without smudges.

Printing on each segment’s edge and not in-between them is the printing challenge of folding meter sticks. And with heat transfers you can achieve just that.

Folding meter sticks printed with digital heat transfers benefit from a high resolution digital print. Not only giving a great price for small quantity multi-color prints, but also being very durable.

Why cosmetic tubes are perfect promotional products? Because they are compact, useful and give enough space for your message.

And we are here to get them printed, also in small quantities!

As a contract decorator who prints your tubes just in time and in almost any quantity, or as your partner for heat transfer machines as well as digital heat transfer decals, we have the perfect solution for you.

What you should know about the advantages of printing different names, languages, numbers and codes – in one run!

Starting with printing different names on promotional products over serialized special editions to a print run with every image being different. With digital heat transfers you can achieve all this. Without UV, without solvents and without stopping your heat transfer machine.

3 sides, 3 different photo-realistic images.

That is what a paper cube box can look like when you print it with DIGITRAN digital heat transfer technology.