Learn about color spaces and color conversions, because only with this knowledge can you print good colors.

Lab color space

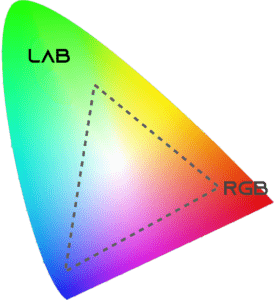

Definition: Lab is a color model developed by the International Committee on Illumination (CIE) that is uniform in terms of perception. It comprises the components lightness (L*), green-red (a*) and blue-yellow (b*). This color space encompasses all colors that can be perceived by the eye and is therefore the largest of the three.

Application: Used in color management and conversion between devices to ensure consistent color reproduction in digital printing and DTF printing.

This is how it works:

Device-independent: Represents colors as they are perceived by the human eye.

Ideal for color correction and consistency.

L* defines the brightness.

a* & b* define the color (hue and saturation).

RGB: Red, green, blue

Definition: RGB is an additive color model that is used for digital displays. This color model is used in particular for PC monitors and televisions. It combines red, green and blue light to create colors. Each color value ranges from 0 to 255, resulting in over 16 million possible colors and thus a large color space.

Application: Ideal for digital screens such as monitors, televisions and smartphones. Here, it is not the light reflected from the surface that is perceived, but the light emitted by the device.

This is how it works:

Additive process: addition of light increases the brightness.

Black = absence of light (0, 0, 0).

White = full presence of light (255, 255, 255).

CMYK: Cyan, magenta, yellow, black

Definition: CMYK is a subtractive color model that is primarily used in printing. It combines cyan, magenta, yellow and black to create colors by subtracting light from white paper. Unlike a monitor, the color is not generated by illuminating LEDs but by reflected light from the surface. The color space is generally smaller than the RGB color space.

Application: Perfect for digital printing such as DTF printers and digital transfers.

How it works:

Subtractive process: ink application reduces the brightness.

White = absence of ink on a white background or by printing white ink (fifth "color").

Black as a separate "color".

CMY as colors with values from 0 to 100.

RGB to CMYK conversion for digital printing

RGB to CMYK conversion: Digital art in RGB mode must be converted to CMYK for printing. RGB offers a wider color space that is not fully reproducible in CMYK, which can lead to color shifts. Previewing and adjusting colors for printing is essential.

Color accuracy: RGB colors appear vibrant on screens, but can look more muted in CMYK. Use ICC profiles to manage these differences. Common color profiles are "sRGB" for the RGB color space and "ISO Coated v2 300%" and "FOGRA39" for the CMYK color space.

Lab color space for conversion: Lab can be used as an intermediate stage to obtain color accuracy when converting from RGB to CMYK. For this purpose, test patches are printed in CMYK on a printing press, the "perceived" color is measured and assigned to a Lab value. In this way, a perceived color can be assigned to a printed color of the machine. With a color profile such as FOGRA39, a perceived color is assigned to each CMYK value.

If a print file has now been created with a profile, the corresponding Lab value can be used from the CMYK value of the file. This in turn is compared with the profile of the machine and a CMYK value is created from the Lab value.

Practical tips for perfect printing results

✔ Create artwork in RGB for the best visual experience on screens.

✔ Use soft proofing in design software to simulate the RGB to CMYK conversion.

✔ Adjust colors and contrast in CMYK to achieve accurate printing results.

✔ Use a color space when saving to enable the translatability of colors.

✔ Use CMYK data for print jobs, as this is closer to the print result than RGB data.

By understanding the RGB, CMYK and Lab color spaces, artists can ensure that their digital printing, DTF printing and DTF transfers deliver vibrant and accurate results. Good color management is the key to achieving the best quality in digital and printed artwork.

Our Colormanagement

We have measured our DTF printers colorimetrically so that we print the colors as you see them. To do this, we printed and measured various color patches and created a profile for our printing machines. This is the only way for photos and logos to look the way they should.

Contact Us

to find out more about high-quality transfers and printing machines!

DTF printers - digital transfers for textiles

Our solution for advanced users.

To be able to produce transfers in digital printing yourself, a DTF (Direct to Foil) printer is the best choice. Such machines consist of a printing unit and a finishing unit, which are built in line. Such a machine system is e.g. the DIGITRAN FlexLine DTF600 MK-II.

This DTF printing machine is equipped with two high-quality and durable print heads and optimized for FlexInk inks. High ink coverage, color fastness, washability and OEKO-Tex certification are just a few of the advantages this system offers you.

In addition, this system relies on a hot-melt powder with which cotton, polyester as well as blended fabrics are easy to print. The powder unit also ensures that the powder is applied evenly to the print without clumping. After tapping, the printed image is dried in a drying tunnel using IR lamps. The printed film is then cooled and wound onto a roll.

Thanks to this fully automatic printing technique, multicolored motifs can be printed quickly, easily and cost-effectively. Without screen production, cleaning or additional drying.

Click on the button to get in touch with us directly and receive personal advice. So that your products can also benefit from this unique, clean and digital printing technology as quickly as possible.

Further Posts

Heat transfer decorating at up to 600 textiles per hour – with a single operator!

This is what the TURBOTRAN 6.1 is build for. The fastest, fully automatic heat transfer machine in the textile industry.

- « Previous

- 1

- 2