Ceramic bottles are perfect to give your spirits a unique look.

Not only do they look different than all those glass bottles, but they will also protect your drink from sunlight!

To apply a heat transfer to a ceramic bottle all you need is to add some extra heat the bottle itself. Anything from an oven or drying tunnel to a flame will do the trick. But if you have a flame treatment available, go for it!

After a few spins in front of the flame the bottle is free from water and ready to be printed. Therefore, you just place the hot bottle in your heat transfer machine. By applying heat and pressure the transfer will release from the carrier and adhere to the bottle. Done.

No primer, no curing, no drying. Once the image is applied the bottle you can fill or pack and ship it right away.

And if you want to add a coating or combine it with another printing technology you can do this, too.

Digital heat transfers are perfect for smaller runs, multi-color designs, and special editions. All this with a photo-realistic print quality of 1200 dpi.

Our services include:

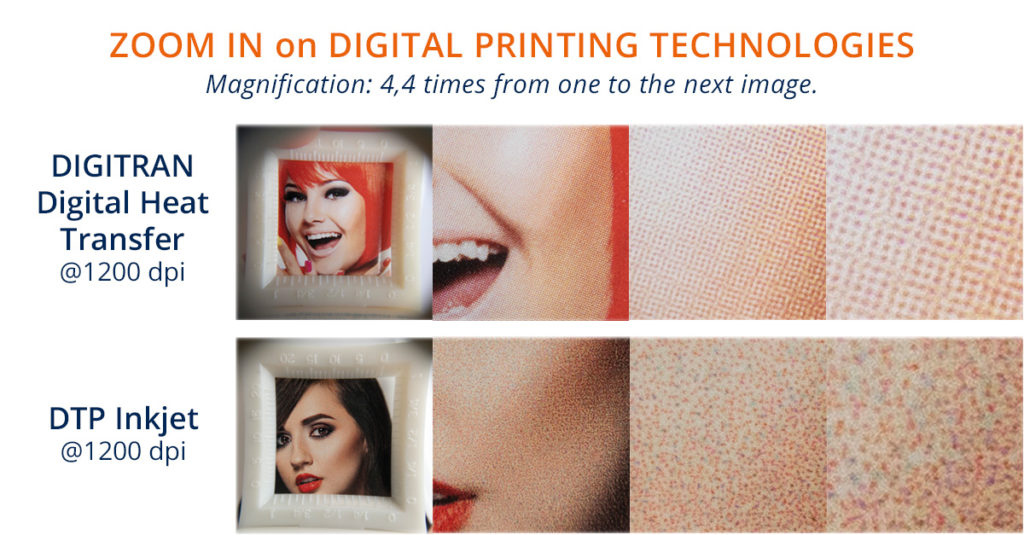

Would you think that 1200dpi and 1200dpi digital printing is the same? You probably would.

But actually no, not even close!

Especially when it comes to photo-realistic printing and skin tones the print quality must be on point. The confusing part is that even though both prints shown in the photo have a resolution of 1200 dpi, they are obviously not the same. But how does that come?

Why cosmetic tubes are perfect promotional products? Because they are compact, useful and give enough space for your message.

And we are here to get them printed, also in small quantities!

As a contract decorator who prints your tubes just in time and in almost any quantity, or as your partner for heat transfer machines as well as digital heat transfer decals, we have the perfect solution for you.

What you should know about the advantages of printing different names, languages, numbers and codes – in one run!

Starting with printing different names on promotional products over serialized special editions to a print run with every image being different. With digital heat transfers you can achieve all this. Without UV, without solvents and without stopping your heat transfer machine.

3 sides, 3 different photo-realistic images.

That is what a paper cube box can look like when you print it with DIGITRAN digital heat transfer technology.

Lip balm comes in pretty much just one shape, which makes the print is even more important for this type of packaging.

With digital heat transfers we ensure that your product will stand out!

Especially when it comes to multi-color designs there is close to none in the shelves. Simply because multi-color designs are difficult to print onto a small lip balm shell and the more colors there are, the more it costs.

To bring more diversity to this product we developed DIGITRAN digital heat transfer decals as well as DIGITRAN heat transfer equipment for it